Tech Pack vs Specification Sheet - What's the difference?

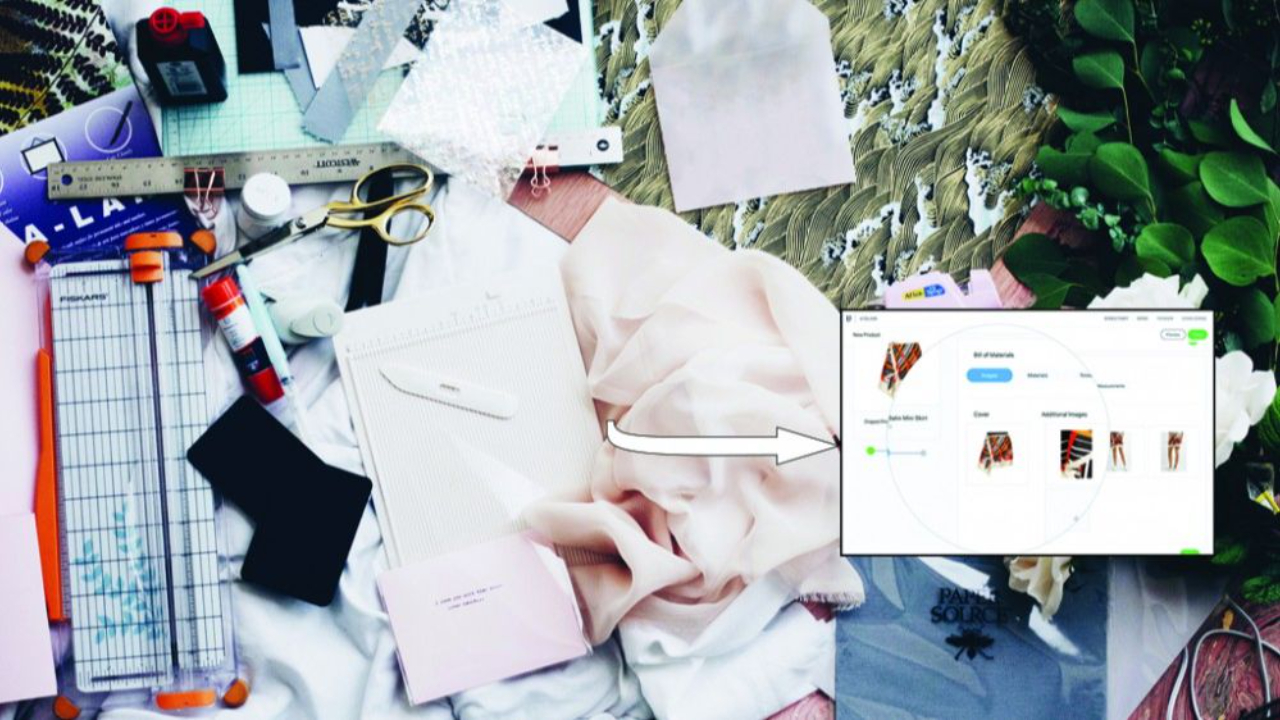

As a designer in the fashion industry, it’s necessary to deal with factories and manufacturers on a regular basis. Whether you use freelance contractors for small production runs or require the services of an overseas factory, one of the requirements of working with them will be to provide a Specification Sheet, in the first instance, followed by a Spec Pack (often referred to as a Tech Pack). Read on to know the difference between a Spec Sheet and a Tech Pack.

[convertkit form=789315]

Many industry newcomers struggle when working with factories until they learn what these working documents are and learn to appreciate their importance. On the other hand, larger brands as well as factories swear by these documents and place the utmost importance on their creation and keeping them up to date.

So what is it that these big brands know that others don't?

Let's delve in and demystify what a Specification Sheet is, why it’s produced, what it should contain and how it differs from a Spec/...

What is a Garment Tech in the fashion industry?

What is a Garment Tech?

[convertkit form=789315]

Prior to purchasing that item of clothing you’ve been coveting for a couple of months, it will pass through many processes overseen by many different experts before it reaches the shop floor. It will be designed by a designer, pattern cut by a pattern cutter and sewn by a machinist. These three people are the ‘stars’ we’re all aware of but who is the person behind the scenes?

The mysterious person who liaises with designers adapts designs to suit production methods, sources fabrics and accessories, undertakes quality evaluations of materials and responds to product queries, including complaints, from wholesalers and customers.

Drum roll, please…

The cog that keeps the wheel turning is the Garment Technologist, commonly referred to as the Garment Tech.

In the past they were typically known as the quality controller, however, their role has now evolved to include the aforementioned in their job description. Considering that there ...

What is "Just In Time" Manufacturing?

In the 1940s the Toyota Motor Company pioneered the concept of Just In Time manufacturing. Its objective was to eliminate waste, inconsistencies, and unreasonable requirements from the production process, thus resulting in improved productivity. It’s a process that can be applied to many different types of manufacturing, but is most famous in the fashion industry, for being applied to Zara's and Uniqlo's fashion supply chains.

Through their partnership with the large textiles manufacturer Toray, Uniqlo uses just in time manufacturing to produce a number of products including their innovative product range Heatech. The thermal underwear products use a chemically-treated smart fabric that uses air pockets to retain body warmth, milk protein for softness, and an antibacterial agent to minimize sweat.

Initially, working with Toray proved a logistical supply chain headache for Uniqlo. Toray, primarily an industrial products manufacturer, operates all year round. Fashion companies usuall...

The Basics of How to Start a Fashion Business

Thinking about how to start a fashion business can be the most exciting thing in the world. Designing your dream line, the prestige of selling your collections in renowned stores, droves of customers buying your products, the glamour of seeing your favourite celebrity wearing your clothes, and the pots of money to be made, are surely very enticing.

However, the reality of how to start a fashion business will be something entirely different to your initial perceived idea.

MARKET POSITIONING & DIFFERENTIATION

Amongst the many things to consider is whether your idea has a place in the market.

If it does – then that’s great.

But if it is similar to many other things out there, you need to figure out how to separate it from the pack and make it distinctive.

It’s actually okay to be similar to something that already exists and is doing well, as that just proves its desirability. However, to find customers and perhaps, persuade your competitors' customers to buy your product instead, it...

Part 2: The Fashion Design Process from Idea to First Sketch

Wanting to launch your own fashion brand is on the wish list of many fashionistas. While many dream about it, only a few get to see their idea realised on paper. The fashion design process takes time and what may have seemed like a simple idea at the start turns into Pandora's box.

In Part 1 of this article, we focused on the research required to develop an initial idea. Continuing from there, we delve into the post-research stage and into the process of ideation.

The most exciting part of the fashion design process is when you have gathered all of your research material and try to make sense of its myriad tentacles, which can take you in many different directions. Prior to reaching this stage though there are a few fundamental tasks you need to focus on.

Try to remember that all of these processes should be fun and that you’re effectively fuelling your creative nous in order to produce interesting new work.

Please note that this article is in continuation of our previous article o...

Cut Make and Trim (CMT) vs Fully Factored (FF) Fashion Manufacturing

Most small fashion brands and industry newcomers underestimate the production process. Not only do they leave it to the end to find a suitable factory, but often they also don't know what is the best way to procure their production and what are the manufacturing options. CMT manufacturing or fully factored manufacturing are often two terms everyone should know of, yet remain often unknown or misunderstood. Let's examine what they mean and how they differ.

[embed]https://www.youtube.com/watch?v=MXm4MF-INnE[/embed]

According to the UK Fashion & Textile Association (UKFT), in 2016 the number of companies manufacturing apparel in the UK rose to 3,830 – a 10.7% increase over the 2015 figures. This is good news, considering the industry had taken a nose dive since the early 1990s. With a marked increase in the use of overseas factories in the East, many local businesses went into receivership.

Now, however, things are changing for the better with the number of employees in textile and ap...

The Importance of Fashion Care Instruction Cards

Keeping your customers educated and aware of how to care for items purchased from you is an important part of the sales game. Care instruction cards are an excellent way to relay your brand values, especially if your products are handmade or use any specialist materials.

By carefully wording your care instruction cards you’ll build brand loyalty, which will help ensure customers return to you and continue to buy your goods.

Thinking through what you include on the care instruction cards from a customer point of view will also protect you should a customer raise a complaint about the quality of the items after purchase and use. If they follow the recommendations then problems shouldn’t occur.

Specific care information relates to different products and these instructions should cover a number of areas including cleaning methods, storing suggestions and any other information that is important to you and relates to the provenance of your goods.

All of the information is traditionally p...

Fashion Product Testing: Basic Tests you Should be Doing Regularly

Fashion product testing enables brands, retailers and manufacturers to ensure the safety, quality and performance of their goods.

Tests can be carried out on items ranging from fabric samples to finished products, including active-wear, apparel for adults and children such as sweaters, sleepwear, outerwear and jeans.

Footwear and fashion accessories such as scarves, belts and bags are also tested. Lest we forget fastenings such as buttons and zips as even these have to be quality and safety assured in order to ensure they’re fit for purpose. These tests are carried out in adherence to a set of Standards which are derived from the combined wisdom of experts in their field.

In every major consumer market, an ever-increasing range of stringent regulations and restrictions for textiles and apparel products are being imposed or are under negotiation. Your products are required to comply with local statutory laws and regulations if you want to sell in a particular market.

Furthermore, fa...

How to size label your clothing range - letters vs numbers

Selecting the correct size label for your clothing range and whether you use letters or numbers sends a clear message about the market you aim to enter.

Their use isn’t based on random selection. Both letters and numbers are used to communicate very different things in the industry.

In regards to sampling size selection, this too should be based on who you hope to appeal to within your market sector. Are they teenagers, thirty-somethings or a much older customer?

Whoever they may be, your ideal target market will inform the decisions you make for your brand.

Universal Lettering vs Numerical Size Labels

In apparel there are two standard labelling size ranges to choose from, depending on your market:

- Letters – XS, S, M, L, XL, XXL are more universal. It is a more generic way of labelling and it is usually suited to less fitted garments.

- Numeric – The Numeric system of size labels relates to a more personalised approach to sizing. Garments that are more fitted will be labell ...

6 Most Widely Used Garment Printing Techniques

Were you aware that there are six, yes six popular methods presently used to transfer coloured patterns onto cloth? No, neither did I.

With so many different available options, it is useful to know what is the best method for different projects, and why are some methods so much more expensive than others?

Let's dive into these printing techniques.

[caption id="attachment_4311" align="aligncenter" width="1280"] Woodblock printing is traditional in India and still widely used.[/caption]

Woodblock printing is traditional in India and still widely used.[/caption]

Woodblock Printing Technique

Woodblock printing is one of the earliest printing techniques. It creates a natural, almost vintage effect on natural fabrics such as cotton, linen and silk.

William Morris used this method, to great effect, for some of his materials. For every colour used in the design, a separate wooden block must be carved. The larger, heavier designs are carved first while the more intricate detailing is left till last.

In some instances, a method, called coppering, in which strips ...